Industrial Blowers

Industrial Blowers – Atlas Copco

Low Pressure Blowers

What Are Low-Pressure Blowers?

Blowers and low-pressure compressors are specifically engineered for applications that require a pressure between 0.3 and 4 bar (g). Massive energy gains can be made by choosing the right type and size of blowers and low-pressure compressors for your applications. Several low-pressure technologies have been introduced into the market, each of them engineered to match the exact pressure and flow requirements of your application.

Industrial Blowers

Air is important for all of us. We need it to live. But did you know that blowers are also crucial in sustaining our lives?

We need blowers to decontaminate manufacturing processes for meat, poultry, dairy products, fruits, vegetables, and beverages. We need them in wastewater treatment facilities to blow air into tanks to accelerate the process of reducing the harm the water can cause. In high-speed print manufacturing systems, we need industrial blowers to rapidly dry printed images. In coal mines, blowers are necessary for providing ventilation to enabler easier and healthier breathing for coal miners.

What’s the Difference Between Blowers and Air Compressors?

A typical blower can look quite similar to an air compressor. However, these devices are fundamentally different.

Think of a blower as a fan that blasts large quantities of air continuously from one location to another, at faster speeds than a typical house fan. Used for heating, cooling, ventilating, and transporting, blowers produce lots of air to create additional airflow, but at relatively low pressure compared with an air compressor.

By contrast, an air compressor squeezes more air into a smaller space at higher pressure intensity than an air blower. It makes the air denser. The purpose is to provide intense pressure to enable tools and applications to work with powerful force.

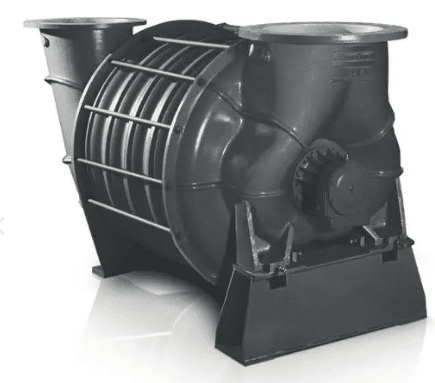

Oil-Free Lobe Blowers

A lobe blower is a positive displacement blower (also known as pd blower) which is typically known for its reliability.

Thanks to their simple design, lobe blowers are a cost-competitive solution in terms of initial capital investment and maintenance costs. The process starts with air entering the unit via the silencer with an integrated inlet filter. The silencer with an integrated inlet filter prevents the air from flowing back to the environment, avoiding pulsation, and ensuring smooth operation. The straight-cut timing gears eliminate axial forces, ensuring trouble-free operation.

Finally, the air then passes through the outlet silencer ensuring low noise emission. The automatic belt tensioning system ensures that the belts transfer power from the motor to the element and are kept tight on the pulleys at all times. Our lobe blower units can easily be connected to your existing piping network via the stainless steel compensator.